VMV10-P is a fully digital Multivariable Pressure and Capacitive Temperature Transmitter designed for differential, gauge and absolute pressure measurements, plus temperature measurement with RTD, TC, Ohm and mV sensors.

The transmitter is powered by a 9 to 32 Vdc voltage and uses the Profibus PA communication protocol in accordance with IEC61158-2 for configuration, calibration, monitoring and diagnostics.

VMV10-P works with the concept of functional blocks, such as Analog Input and Totalizer. Profibus PA configurator, Android platform or tools based on EDDL or FDT/DTM can easily configure the transmitter. In addition, it is possible to configure the VMV10-P via local adjustment using a magnetic key.

The DTM Library for Profibus-PA devices can be found on:

Profibus-PA

Pressure:

| Accuracy | Standard Model: ± 0.075% High Performance Model: ± 0.05% |

| Output Type | Linear, Square Root and User Table |

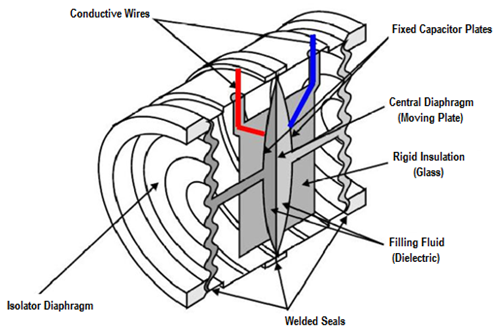

| Sensor Type | Microprocessed capacitive sensor, digital reading and temperature and pressure compensation algorithm |

| Model / Range | D1 / -7.5 to 7.5 kPa (-765 to 765 mmH2O) D2 / -37.4 to 37.4 kPa (-3814 to 3814 mmH2O) D3 / -186.8 to 186.8 kPa (-1.9 to 1.9 kgf/cm2) D4 / -690 to 690 kPa (-7 to 7 kgf/cm2) D5 / -2068 to 2068 kPa (-21 to 21 kgf/cm2) D6 / -6890 to 6890 kPa (-70.2 to 70.2 kgf/cm2) M1 / -7.5 to 7.5 kPa (-765 to 765 mmH2O) M2 / -37.4 to 37.4 kPa (-3814 to 3814 mmH2O) M3 / -100 to 186.8 kPa (-1 to 1.9 kgf/cm2) M4 / -100 to 690 kPa (-1 to 7 kgf/cm2) M5 / -100 to 2068 kPa (-1 to 21 kgf/cm2) M6 / -100 to 6890 kPa (-1 to 70.2 kgf/cm2) M7 / -0.1 to 20.68 MPa (-1 to 210.9 kgf/cm2) A2 / 0 to 37.4 (0 to 3814 mmH2O) A3 / 0 to 186.8 kPa (0 to 1.9 kgf/cm2) A4 / 0 to 690 kPa (0 a 7 kgf/cm2) A5 / 0 to 2068 kPa (0 to 21 kgf/cm2) A6 / 0 to 6890 kPa (0 to 70.2 kgf/cm2) H2 / -37.4 to 37.4 kPa (-3814 to 3814 mmH2O) H3 / -186.8 to 186.8 kPa (-1.9 to 1.9 kgf/cm2) H4 / -690 to 690 kPa (-7 to 7 kgf/cm2) H5 / -2068 to 2068 kPa (-21 to 21 kgf/cm2) |

| Static Pressure and Overpressure Limits | Range 1: 8 MPa (81.6 kgf/cm2) Range 2 to 6: 16 MPa (163.1 kgf/cm2) Range 7: 40 MPa (407.9 kgf/cm2) |

| Stability (1) | Standard Model: ±0.2%*URL (5 years) High Performance Model: ±0.2%*URL (15 years) |

| Rangeability | 150:1 or 200:1 (according to model) |

| Response Time | 100 ms |

| Totalization | Non-volatile volumetric and mass flow |

(1) For temperature changes of ± 20°C, relative humidity 0-100%, line pressure up to 7 MPa (70 bar), installation according to good practices and assembly suitable for processes where hydrogen atoms can be generated (migration of hydrogen).

Temperature:

| Ambient Temperature Effect (1°C variation) | Resistive Sensors: ± 0.0052% of Ohm reading Millivoltage Sensors: ± 0.001% of mV reading |

| Accuracy | According to Sensor Tables (see catalog). |

| Measurement Stability | ±0.1% os reading or 0.1°C – larger value RTD: 3 years; Thermocouple: 2 years |

| Electrical Isolation | Galvanic Isolation, 1.5 kVac |

General:

| Power Supply / Quiescent Current | 9 to 32 Vdc, no polarity / 12 mA |

| Communication Protocol | Profibus PA, according to IEC 61158-2 (H1), voltage mode 31,25 Kbits/s bus-powered. |

| Function Blocks | 3 x Analog Input (AI) and 1 x Totalizer |

| Hazardous Area Classification | Explosion Proof and Instrinsically Safe (pending) |

| Ambient Temperature Limits | - 40 to 85°C |

| Humidity Limits | 0 to 100% RH (relative humidity) |

| Write Protection | Hardware and software with display indication icon. |

| Configuration | Tools based on EDDL and FDT/DTM or Android® platform. |

| Assembly | On field using bracket for Ø 2” tube |

| Protection Degree | IP67 |

| Housing Material | Aluminum |

| Approximate Weight with Bracket | 4 kg |

Main Benefits: